PVC foam board is a versatile and lightweight material widely used in various industries. Made from polyvinyl chloride (PVC), it features a fine, uniform cell structure that provides an excellent combination of strength, durability and flexibility.

PVC foam board sheets are preferred due to the key features below:

- Lightweight but strong: PVC foam boards are lightweight, making them easy to handle and install while maintaining high strength and rigidity.

- Durable and weather-resistant: These boards resist water, chemicals, and UV rays, making them suitable for both indoor and outdoor applications.

- Customizable: PVC foam boards can be easily cut, shaped, painted, or printed, offering versatility for creative and industrial uses.

- Eco-friendly: This material is recyclable and lowly impacted, appealing to environmentally conscious users.

PVC foam boards are used across multiple sectors due to their adaptability, including:

- Signage and advertising: Ideal for creating durable and vibrant signs, displays, and exhibition panels, easy to emboss.

- Construction: Used as cladding, insulation, and partitioning material.

- Furniture and interior Design: Lightweight, moisture-resistant boards are popular for cabinetry, wall panels, and decorative elements.

- DIY Projects: Easy to work with, PVC foam boards are a favorite among hobbyists and crafters.

PVC foam boards offer an economical, durable, and versatile solution for a wide range of projects. Their ease of customization and low maintenance requirements make them a preferred choice for professionals and DIY enthusiasts alike.

By choosing high-quality PVC foam boards, you can ensure lasting performance and a polished finish for your projects. For more insights or purchasing options, feel free to explore our range of premium PVC foam boards today!

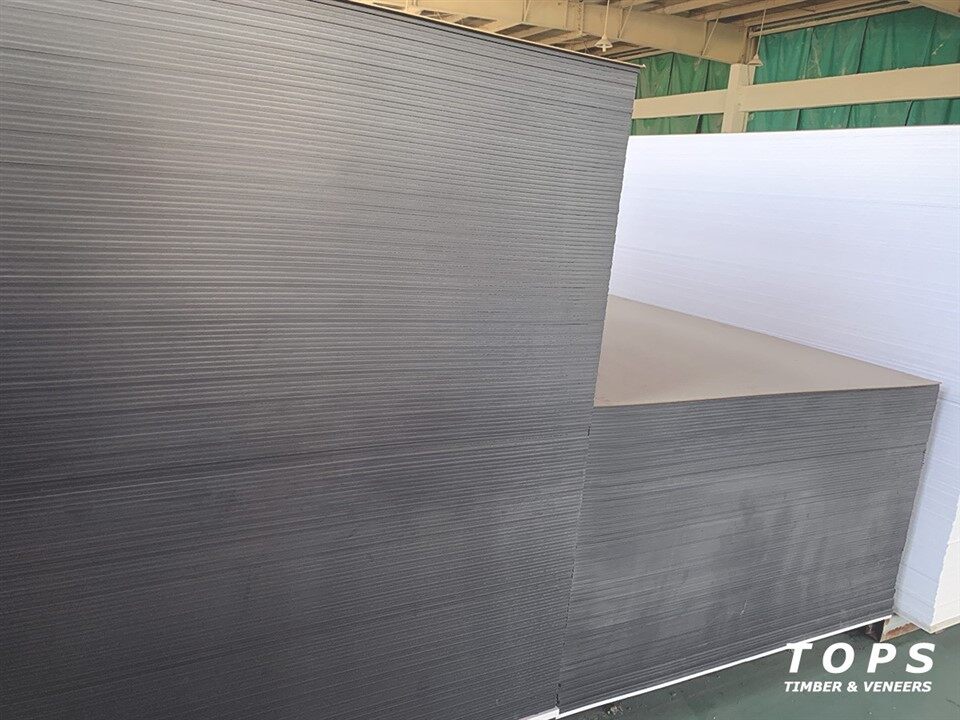

Color: white, black, biege, green ...

Thickness: 3-30 mm

Face Laminate: PVC film, PET film

| Physical Properties | Unit | Value |

| Density | kgs/cbm | 400-800 |

| Tensile Strength | mpa | ≥10 |

| Bending Strength | mpa | ≥20 |

| Rupture Elongation | % | ≥15 |

| Water Absorption | % | ≤0.2 |

| Hardness | D | ≥55 |

| Softening Temperature | °C | ≥75 |